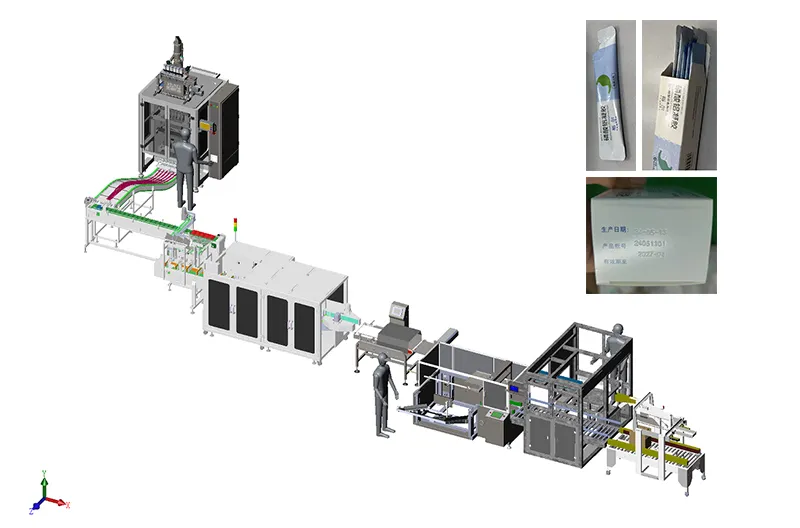

Complete Packaging Line

The packaging line is designed to achieve a production capacity of 3,600 bags per hour, ensuring a clean and low-noise operational environment. Built for efficiency, it integrates bag forming, sealing, packaging, and date printing into a single smooth process.

Equipped with advanced motion bus PLC control and a multi-language touch screen, the machine offers easy operation and precise adjustments. Its stable control system allows for parameter changes, such as production speed and batch size, without stopping the machine. The built-in fault diagnosis system and the ability to store up to 100 parameter sets ensure quick product transitions and minimal downtime.

Our packaging line features a multi-point, one-button start mechanism, providing coordinated control across all sections. An Ethernet port allows simple integration into EMS systems, enabling full process monitoring. Safety is prioritized with automatic fault alarms and a shutdown feature activated when the protective cover is open, fully complying with CE safety standards.

This high-quality packaging line offers reliability, efficiency, and advanced features to meet the demands of modern production facilities. It is the ideal solution for businesses looking to improve performance and maintain high-quality packaging standards.

Designed for automatic weighing and packaging of granular materials in the food, pharmaceutical, and chemical sectors. The packaging process prevents oxidation, mold growth, spoilage, and moisture damage, effectively preserving quality, freshness, and extending product shelf life.

- 1.Inner Bag Packaging The 6-lane packaging machine completes the inner bag packaging and outputs the finished bags.

- 2.Automatic Sorting and Conveying The automatic sorting conveyor organizes the inner bags based on the required box quantity and arrangement.

- 3.Box Placement Sorted inner bags are placed onto the conveyor of the cartoning machine, preparing for boxing.

- 4.Automatic Cartoning Inner bags are automatically boxed, with the case erector machine opening boxes for the process.

- 5.Box Loading Boxes are automatically conveyed to the case packing machine, where they are prepared for loading.

- 6.Quality Check and Packing After passing the weight check, products are automatically conveyed to the sorting and case packing machine for organized placement and packing.

- 7.Sealing and Strapping Completed boxes are transported to the automatic carton sealing and strapping machine for sealing and strapping, before being sent out.