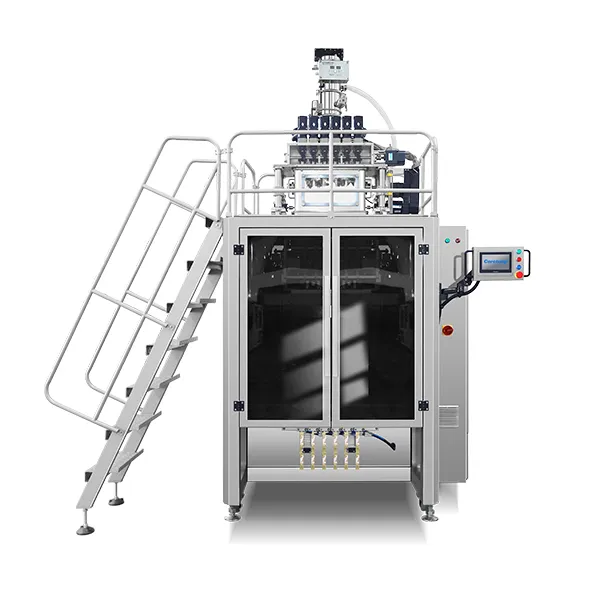

With over a decade of experience in manufacturing packaging equipment, we offer high-performance solutions tailored to your packaging needs. Our comprehensive service system ensures a smooth experience, from pre-sale customization to delivery and ongoing support. If you’re interested in our company or equipment, please get in touch with us today!